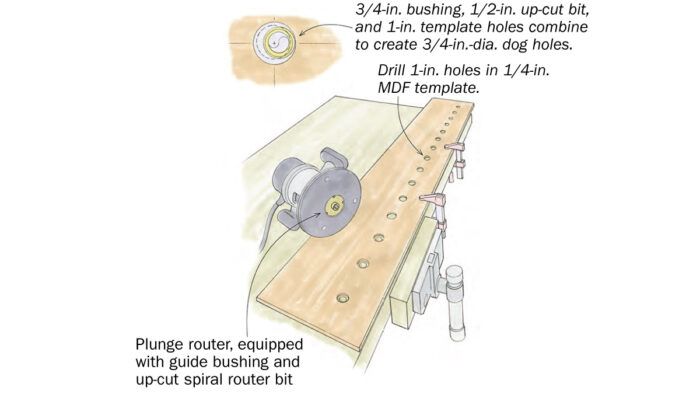

Dog holes can be difficult to drill in a workbench. A 3⁄4-in. bit is hard to control by hand, and hard to keep square to the bench. So I turned to my plunge router instead, using a 3/4-in. guide bushing, a 1/2-in. up-cut spiral bit, and a very simple template with 1-in.-dia. holes in it to produce the 3/4-in. dog holes I needed. I drilled the template on the drill press, spacing out an entire row of dog holes on it. After routing that row, I repositioned the template to rout additional rows.

Depending on the thickness of your workbench top, you might not have the bit length and/or plunge capacity needed to get through it. If not, you have a few good options. Try plunge cutting as far as you can, then reaching deeper with a top-bearing router bit, which will follow the existing holes; or use a 3/4-in. Forstner bit to finish them with a handheld drill, keeping the drill shaft centered in the hole. You could also drill through with a 5/8-in. bit, and work from the underside with a bottom-bearing router bit.

—JOE WEISS, Greene, N.Y.

Illustrations by Dan Thornton

From Fine Woodworking issue #293