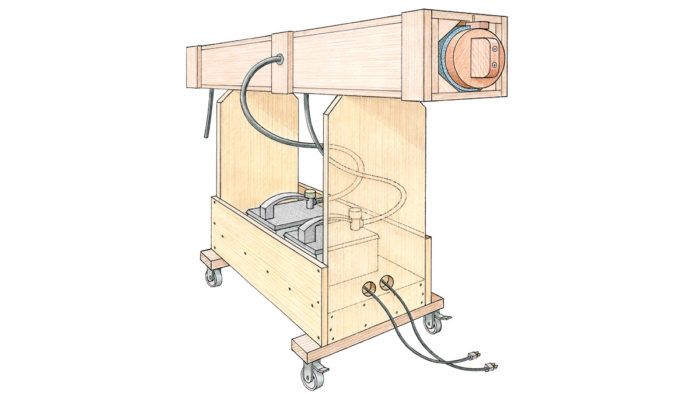

The simplest steamer I ever made was a stovepipe set into a saucepan on the kitchen stove. I balanced chair legs in the pipe and stuck a rag in the top to keep steam from escaping. If you have only a bit of steaming to do, or want to experiment before investing in a proper steambox, stovetop steaming will get you by. The key thing in setting up a steamer, no matter how robust or economical the system, is getting enough steam in the box. So what is enough? While I can’t give you a number of BTUs or tell you how much water is sufficient, the wood can. After 15 to 20 minutes of steaming, the wood should be dripping when you pull it from the chamber. If it isn’t, you will likely need to deliver more steam or build a smaller chamber. In a smaller chamber, the same amount of steam can more fully saturate the space and better plasticize the wood. I use a thermometer mounted in the door of my steambox to see that I’m getting 200° in the chamber. Earlex steam generators (or similar steamers, like those for removing wallpaper) can do the job on a small scale, but you might need two of these to fully saturate a steambox like the one drawn here. You can use a CPVC pipe alone as a quick steambox. It can handle the heat and contain the steam. But it may get soft and lose its form unless you support it well while steaming.

Sources of supply:

Earlex Steam Generator, leevalley.com

Galvanized Stamped Steel Grate, standartpark-usa.com

High Density Polyethylene, 8 in. dia., hdpesupply.com

Illustrations: Vince Babak

From Brian’s article “How to bend wood to your will” which is featured in Fine Woodworking #287.

How to Create Curves with Bent Lamination

Creating Curved Furniture